Línea de Producción de Galletas Duras y Suaves YJ-1000 de Guinea. Una empresa alimentaria en Guinea planea introducir una línea de producción moderna de galletas. Después de realizar extensas investigaciones y comparaciones, finalmente decidió asociarse con nuestra empresa. Nuestra compa...

Contáctenos

Línea de producción de galletas duras y blandas YJ-1000 de Guinea

Una empresa alimentaria en Guinea planea introducir una línea moderna de producción de galletas. Después de realizar extensas investigaciones y comparaciones, finalmente eligió asociarse con nuestra empresa.

Nuestra empresa desarrolló e instaló de forma independiente una línea de producción completamente automatizada de galletas, adaptada a los requisitos del cliente y a las condiciones del lugar. Basándonos en las características de las materias primas locales de Guinea, optimizamos y mejoramos el módulo de preprocesamiento de materias primas, añadiendo funciones como la selección de materiales y la precisión ajustable del molido, para garantizar la compatibilidad total con los procesos productivos posteriores. Para hacer frente a las condiciones locales de suministro eléctrico, empleamos motores de bajo consumo y un sistema inteligente de control ahorrador de energía, reduciendo así el consumo eléctrico de la línea de producción. Asimismo, se integró una interfaz para fuente de alimentación de emergencia, asegurando el funcionamiento continuo en condiciones extremas. Teniendo en cuenta el entorno de alta temperatura y alta humedad, se seleccionaron materiales premium resistentes a la corrosión y al calor para los componentes principales del equipo, mejorando su adaptabilidad ambiental.

Nuestra empresa ha establecido un equipo de servicio de proyectos dedicado para supervisar el progreso del proyecto durante todo el proceso. El equipo técnico trabaja en el lugar para completar de manera eficiente la instalación y puesta en marcha del equipo. Adaptado a las características de los operadores locales, realizamos capacitaciones operativas fáciles de entender para garantizar que dominen hábilmente las habilidades de operación del equipo. Para el mantenimiento posterior a la instalación, hemos implementado un mecanismo de respuesta de emergencia las 24 horas. Combinando orientación remota con inspecciones periódicas in situ, ofrecemos servicios de mantenimiento oportunos y profesionales a nuestros socios.

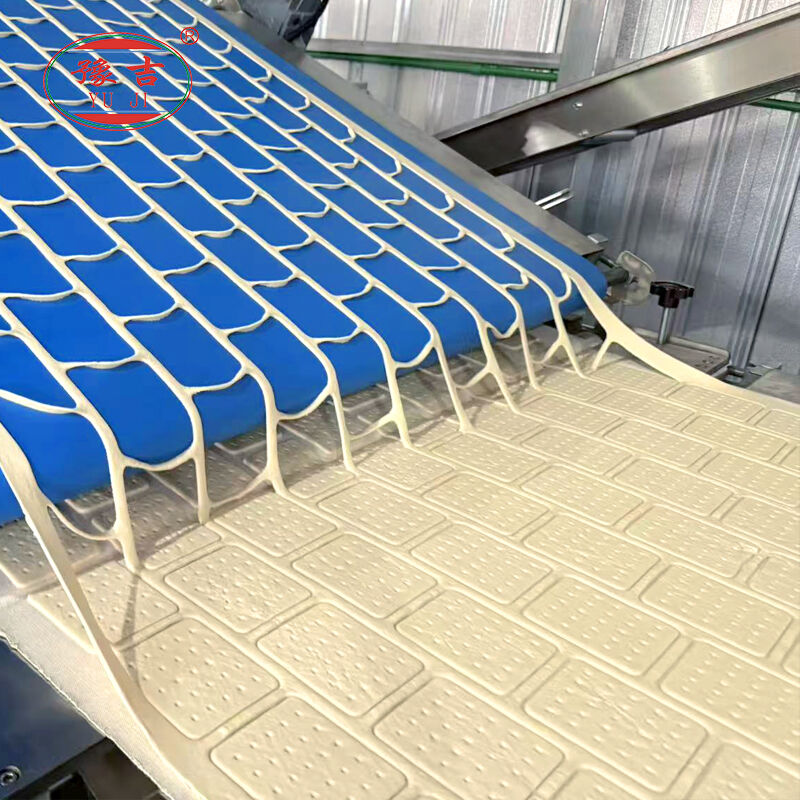

Durante la prueba, la línea de producción funcionó sin problemas durante todo el proceso, produciendo con éxito varias variedades de galletas de alta calidad adaptadas al gusto local. Todos los indicadores de rendimiento cumplieron con los estándares preestablecidos, obteniendo un alto reconocimiento por parte de los socios guineanos y representantes de la industria alimentaria local. Esto marca el despliegue exitoso del equipo de procesamiento de alimentos de nuestra empresa en Guinea, inyectando un nuevo impulso al desarrollo de la industria alimentaria local.

Esta línea de producción de galletas exportada emplea tecnología de control completamente automatizada en todo el proceso, logrando operaciones automatizadas desde la entrada de materias primas hasta el envasado del producto terminado. Esto no solo mejora significativamente la eficiencia de producción, sino que también minimiza el impacto de la intervención humana sobre la calidad del producto. Además, está equipada con un sistema de monitoreo inteligente que permite el seguimiento en tiempo real de los indicadores clave durante la producción, permitiendo a los operadores ajustar rápidamente los parámetros según sea necesario. Con alta automatización, excelente eficiencia productiva, bajo consumo de energía y operación fácil de usar, esta línea ofrece una adaptación flexible a las características locales de las materias primas y a las demandas del mercado mediante formulaciones de productos y especificaciones ajustables. Es capaz de producir galletas blandas, galletas duras y crackers salados.

Los socios guineanos han elogiado altamente la calidad, el rendimiento y los estándares de servicio de la línea de producción, declarando explícitamente su intención de basarse en esta colaboración y profundizar aún más la cooperación con nuestra empresa en el sector de la industria alimentaria.